Installation And Maintenance Guide

CONNECTION

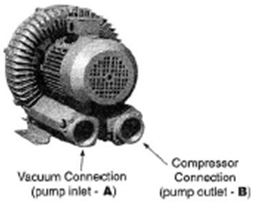

For vaccum operation, connect the suction pipe to connection A, and for pressure operation connect the pressure pipe to connection B (See Figure). Install startup screens before startup to protect pump from debris.

SPECIAL NOTE

For alteration between Vacuum and Pressure application, changeover valves should be used. Use of changeover valve allows the same connection to be used for both Vacuum and Pressure

Maintenance / Repairs / Troubleshooting

| Fault | Cause | Remedy |

| Motor does not start or motor noise | At least two power supply leads interrupted | Eliminate interruption by fuses, terminals or power supply cables. |

| Motor does not start or humming noise | One power supply leads interrupted | Eliminate interruption by fuses, terminals or power supply cables. |

| One or more phase of winding open | Repair / Replace motor winding | |

| For a single phase motor - capacitor open | Change capacitor | |

| Impeller is jammed | Open blower front cover, remove foreign body and clean | |

| Check or correct impeller gap setting if necessary. | ||

| Impeller is defective | Replace impeller | |

| Rolling bearing on drive motor side / blower side defective | Replace motor bearing / blower side bearing | |

| Protective motor switch trips when motor is switched on. Power consumption too high. | Winding short circuit | Have winding checked |

| Motor overloaded Throttling does not match specification on rating Label. | Reduce throttling | |

| Clean filters, mufflers and connection pipes if necessary | ||

| Power source unbalanced | Check & rectify power source | |

| Blower is jammed | See fault “Motor does not start humming noise. “With cause: “impeller is jammed.” | |

| Blower unit does not generate any or generate insufficient pressure difference. | Leak in system | Seal leak in the system |

| Wrong direction of rotation | Reverse direction of rotation by interchange two connects leads. | |

| Incorrect frequency (on Blower units with frequency converter). | Use Correct frequency | |

| Different density of pumped gas. | Take conversion of pressure values into account. Inquire with us. | |

| Shaft seal defective | Replace shaft seal. | |

| Change in blade profile due to soiling | Clean impeller, check for wear and replace if necessary | |

| Abnormal flow Noise | Flow speed too high | Clean pipes. Use pipe with larger cross-section if necessary |

| Muffler soiled | Clean muffler inserts, check condition and replace if necessary | |

| Abnormal running noise | Ball bearing lacking grease or defective | Regrease or replace ball bearing |

| Blower leaky | Seals on muffler defective | Check muffler seals and replace if necessary |

| Seals in motor area defective | Check motor seals and replace if necessary |